al 7075 charpy impact test|charpy impact testing pdf : manufacturing In the present study Charpy impact tests on a 7075-T651 aluminium alloy with full size (55×10×10 mm) with different notch tip radius (range of 0.19 to 0.40 mm) were conducted and . webNovel. Início. Comédia. God Jangsan Tiger. Ler primeiro Ler último. Gênero (s) Comédia, Escolar, Fantasia, Josei, Manhwa, Romance. Hong Sia é alguém que não tem sorte com .

{plog:ftitle_list}

Ô de Casa. Uma tempestade de verão acaba trazendo convidados inesperados à casa de Kyle. Será que ele vai resistir à todas as surpresas até que a situação se ajeite? Leia o primeiro capítulo.

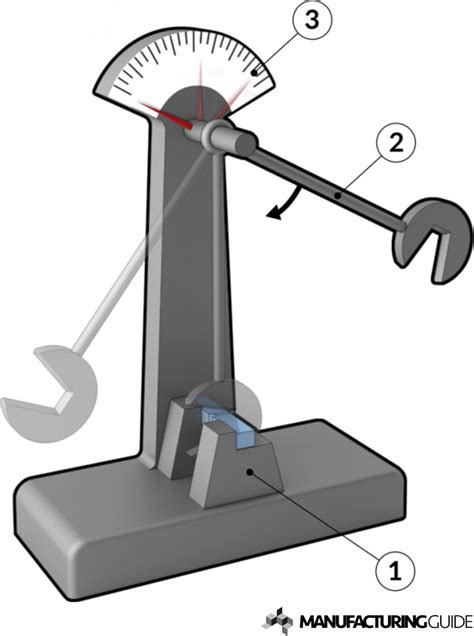

leaf spring testing machine

In the present study Charpy impact tests on a 7075-T651 aluminium alloy with full size (55×10×10 mm) with different notch tip radius (range of 0.19 to 0.40 mm) were conducted and .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

The Charpy impact test behavior of base metal, weld metal, and heat‐affected zone for 6061‐T6 and 7075‐T651 aluminum alloy welds was analyzed. Force versus time curves of welded joints were. Charpy V-notch test results revealed that the energy absorption ability of the 6061-T6 Al alloy is roughly two times higher than the 2024-T4 and roughly four times higher than the 7075-T6. By using an instrumented impact pendulum, the force versus time curves of 7075-T651 aluminum welds were obtained from standard Charpy-V samples. Considering the . Aluminum alloys Al6061T6 and Al7075T6 aluminum alloys purchased from Hindalco Industries Limited’ (Aditya Birla Group) were considered to investigate the effect of .

coil spring testing machine

The Charpy impact test behavior of base metal, weld metal, and heat-affected zone for 6061-T6 and 7075-T651 aluminum alloy welds was analyzed. Force versus time .impact energy from the Charpy V-notch test, for 6061-T6, 2024 -T4 and 7075-T6 aluminium alloy. His results reveal that among the aluminium alloys, 6061-T6 has the greatest impact . Charpy V-notch test results revealed that the energy absorption ability of the 6061-T6 Al alloy is roughly two times higher than the 2024-T4 and roughly four times higher than the 7075-T6 Al alloy.In the present study, the Charpy impact test on the 7075 aluminum sample performed in full size 55×10×10 mm with different notch depth and the fracture energy is measured. The force-displacement .

In the present study, the Charpy impact test on the 7075 aluminum sample performed in full size 55×10×10 mm with different notch depth and the fracture energy is measured. The force-displacement . Estimation of fracture toughness (K IC) using Charpy impact test for Al6061T6 and Al7075T6 alloys subjected to corrosion. Author links open overlay panel S. Sunil Kumar a b, Neelakantha V. Londe b, K. Dilip Kumar c, . Study of the SCC behavior of 7075 aluminum alloy after one-step aging at 163 C. J. Mater. Eng. Perform. (2013) View more .

Abstract: In the present study Charpy impact tests on a 7075-T651 aluminium alloy with full size (55×10×10 mm) with different notch tip radius (range of 0.19 to 0.40 mm) were conducted and the . In the present study, the Charpy impact test on the 7075 aluminum sample performed in full size 55×10×10 mm with different notch depth and the fracture energy is measured. The force-displacement .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . The Charpy impact test behavior of base metal, weld metal, and heat-affected zone for 6061-T6 and 7075-T651 aluminum alloy welds was analyzed. Force versus time curves of welded joints were obtained by means of an instrumented Charpy pendulum.

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.Download Table | Charpy impact test results for 6061 aluminum alloy quenched in different media from publication: Investigation of the Quenching Properties of Selected Media on 6061 Aluminum Alloy .

Master the ductile-to-brittle transition temperature of 6061 aluminum. Understand its impact on performance and applications. Read our detailed guide! Call Us Now (408) 294-2334 . the Charpy Impact Test, also known as the Charpy V-notch test, is conducted to determine the toughness of a material. . Almost all except 7075-T6 and 7178-T6-100 .

Charpy V-notch Testing and Aluminum. Aluminum is different. As a face-centered cubic material, it has no DBTT. As the temperature is lowered, aluminum becomes stronger but remains ductile. In fact, aluminum alloys are ductile even at liquid helium temperatures (-425 degrees F). That’s why aluminum alloys are used so often in fabricating .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.Keywords: Fracture toughness, Charpy V-notch test, Deformation behavior, 2024-T4 Al alloy, 6061-T6 Al alloy, 7075-T6 Al alloy. * Corresponding author. Email: [email protected] In order to characterize the mechanical properties of the multilayer material, we performed Charpy impact testing. The results of the Charpy impact testing are reported in Table 1. The Charpy V-notched (CVN) energy average value for the monolithic Al 7075-T6 (D) was 62 kJ m −2 and for the Al 1050-H24 (H) was 333 kJ m −2.

This work presents an experimental evaluation of yield strength, tensile strength, and impact toughness of 7075 Al alloy. The extended finite element method (XFEM) has been chosen for quasi-static crack growth simulations using Charpy impact energy as the crack growth criterion for both Bulk and ultrafine-grained (UFG) 7075 Al alloy. The 7075 Al alloy is rolled for .This research paper, reports a comparative analysis of tensile and impact-toughness behavior of cold-worked and recrystallized 7075 aluminum alloy. The Charpy test sample method of impact testing does possess certain advantages; these include ease of preparation, simplicity of test method, speed, low cost per test, and low cost in test .The Al 7075 alloy was rolled for different thickness reductions (40% and 70%) at cryogenic (liquid nitrogen) temperature and its mechanical properties were studied by using tensile testing, hardness, and Charpy impact testing.

The Charpy impact test behavior of base metal, weld metal, and heat‐affected zone for 6061‐T6 and 7075‐T651 aluminum alloy welds was analyzed.26]. This study presents variations of materials tested with the instrumented Charpy impact test, namely Stainless Steel 304, Aluminum Alloy 6061-T6, and Aluminum Alloy 7075-T6. The Charpy machine records the energy absorbed value and the impact strain signal is simultaneously recorded during the impact test. These

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . The Charpy impact testing is the most common method to assess the absorbed impact energy [[1], [2], [3]]. . 6061-T651 and 7075-T651 aluminum alloys were tested under orthogonal impact tests at different strain rate. Although, the 7075-T651 alloy has a yield stress of approximately 53% more than 6061-T651 with a similar hardening strain .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.26]. This study presents variations of materials tested with the instrumented Charpy impact test, namely Stainless Steel 304, Aluminum Alloy 6061-T6, and Aluminum Alloy 7075-T6. The Charpy machine records the energy absorbed value and the impact strain signal is simultaneously recorded during the impact test. These

charpy testing

Aluminum alloy-based metal matrix composites (AMMCs) are the most common material used in the field of automotive sectors because of their lightweight, economical, high strength-to-weight ratio, anti-corrosive properties, and large-scale availability. In the present study, Al7075-T6 as a base matrix with silicon carbide (1.5, 2.5, and 3.5 wt.%), graphite (2, 3, and 4 .The Charpy impact test behavior of base metal, weld metal, and heat-affected zone for 6061-T6 and 7075-T651 aluminum alloy welds was analyzed. Force

charpy impact testing pdf

charpy impact testing definition

Em resumo, nenhuma. Quando acrescentamos ferramentas .

al 7075 charpy impact test|charpy impact testing pdf